Mechanical Anchoring

By Administrator

In the construction industry, we often need to connect one thing to another. The kind of fastener or anchor you need for every connection depends on a few different variables:

- The base

- The element we want to connect to the base

- The loads this connection will be subject to

- The length of the fastener or anchor.

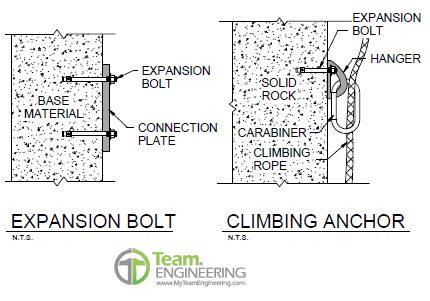

If the base is a hard surface like concrete, masonry or stone, we can consider using a mechanical anchor. Mechanical anchors are also used more often in post-installed applications (i.e. after the base material has been built). There are several different mechanical anchoring systems, but most of them rely on some form of expansion. When we install a mechanical anchor in a base material hole and then expand the anchor, it uses friction and geometry to secure the connection. For this reason, they are often called “expansion bolts.”

At Team Engineering, we most commonly see expansion bolt anchors when connecting baseplates, ledgers, beam/joist hangers, railings, etc. to concrete walls and footings. Mechanical anchors come in many shapes and sizes—typically as anchors increase is length and diameter, they can support greater loads. These anchors are usually subject to shear and uplift loads which must be analyzed by a building design professional so that they can be appropriately specified.

Mechanical anchors are not only used in the construction industry, though. They are also used in the rock climbing industry. When rock climbing, the first climber (‘lead’ climber) brings the rope up the wall as they climb. The lead climber needs to protect themselves from falling. One way to protect a fall is by running the rope through mechanically anchored hangers. An expansion bolt connects the hanger to the rock, and a carabiner connects the climbing rope to the hanger. When the lead climber falls, they will fall a short distance until the rope (and belayer below) catches them at the anchor point.

On rocks and buildings, it is critical that mechanical anchors are installed correctly. Installation depends on the manufacturer. It’s also a good idea (especially when rock climbing) to inspect expansion bolts and base material for signs of movement or failure. This is one of the pitfalls of expansion bolts–they are more prone to movement over time than other anchoring systems because buildings and rocks expand and contract due to temperature and moisture levels. That said, the connection between expansion bolts and a solid base material should last a very long time when analyzed, designed, and installed correctly.

More Articles From...

| This Category | Educational Training, Engineered Consultations, Home Repairs, Residential Engineering, Structural Design, Structural Engineering |

| This Author | Administrator |