Installing Closed Cell Spray Foam in Lifts

By Team Engineering

Closed-cell 2-lb/ft3 (32 kg/m3) “high density” spray polyurethane foam has tremendous adhesive and strength properties as well as high thermal resistance and air tightness. This type of spray foam is often installed on the underside of roof sheathing, and if the bond between the closed-cell spray foam and the underside of the roof sheathing fails, it fails quickly. And it lets everyone know that it has failed quickly with a very loud pop!

There are a couple of reasons this type of failure can occur. The most common are thermal shock in the winter, poor installation technique, or overheating of the foam during installation. If the spray foam is installed in layers (“lifts”) that are too thick, the heat buildup from the exothermic reaction in the foam can be intense. This can be exacerbated by too-hot substrates, i.e., summer work on the south elevation with black underlayment or roofing. This can result in a core density that is too low, and that makes the spray foam dimensionally unstable in the core, making it difficult for the spray foam to handle thermal stress. The resulting thermal stress is often the greatest during cold weather. So, the “failure” can happen months after the installation.

When installing spray foam, the maximum thickness per pass or per “lift” is determined by the manufacturer as the chemistry varies from manufacturer to manufacturer. Typical “lifts” vary between 2 inches and 5 inches.

Always follow the manufacturer’s recommendations and consider them as “requirements”. Several passes or lifts are typically required to meet the thermal resistance requirements of the assembly. The installed foam in each pass or lift needs to dry or “cool” before the next pass or lift is applied.

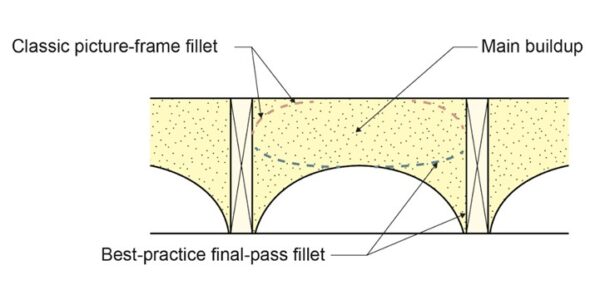

Figure 1 illustrates good installation practice that maximizes surface bonding. It is referred to as a “classic picture-frame” installation…” doubled up”. The perimeter of the “framing bays” are sprayed first with a “fillet” of foam prior to the application of the “main” buildup followed by a second layer of “picture-framing”.

Key points to keep in mind: It’s very important for sheathing and framing members that the spray foam is expected to adhere to be completely dry before the insulation is applied. Moisture-laden framing can cause the spray foam to fail.

Also, it’s best to apply foam to the underside of roofs when they are cool. Direct sunlight on the roof can exacerbate the exothermic reaction effect.

More Articles From...

| This Category | Home Repairs, Residential Engineering, Structural Engineering |

| This Author | Team Engineering |