THE BEST WAYS TO UPGRADE OLD WOOD SHEAR WALLS

By Brian Ki, P.E.

Older New England buildings often lack the lateral force resisting structure to meet modern loading requirements, making them difficult and costly to repurpose when the Code requires improvements.

We’ve been challenged on many projects to increase shear wall capacity in a practical manner to facilitate continued use of old buildings. Here are successful approaches we’ve taken:

SHEATHING:

EXISTING CONDITION

Horizontal wood planks were the go-to sheathing material before plywood and OSB became mainstream in the middle of the century. These planks often varied in dimensions, controlled by the size of local trees harvested and milled on-site. Thicknesses of 1” and widths varying between 6”-12” are common. Shear loads in walls are horizontal, and there is no theoretical shear capacity of a horizontal plank assembly.

IMPROVEMENTS

- Add a layer of modern structural sheathing outside the plank. Or sheathing can be added to the inside face of the wall, but that makes interior utilities installation more difficult.

- Supplement with other lateral force resisting systems. These include let-in bracing, gypsum board sheathing, and wood portal frames. With any of these methods, the existing framing must tie into the new system for the loads to transfer properly.

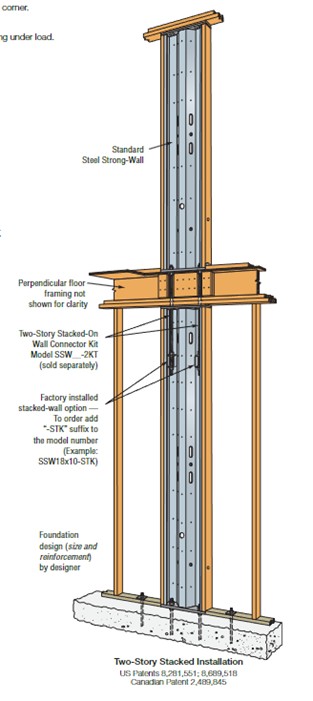

- Custom steel frames or proprietary systems. Steel moment frames or proprietary shear wall products, such as those available from Simpson Strong-Tie, are stronger but more expensive.

BALLOON FRAMING:

EXISTING CONDITION

- The standard balloon framing included continuous studs that by-passed the floor, and the floor joists attached with a ledger or let into the inside face of the studs . Wall segments of this construction often have limited capacity because of the small width-to-height ratio, and necessary load transfer to and from intermediate floor diaphragms is limited.

IMPROVEMENTS

- Break the continuous studs at each floor. Cut the studs at each floor level and install a new bottom plate. The gap behind the ledger would need to be filled with shear blocking, which can also act as required fire blocking. This new assembly will act more closely to a platform framed constructed building and create the proper wall interaction with the floor diaphragm.

- Install hold-downs. Hold-downs between floors and at the foundation are necessary to transfer the vertical chord force at the ends of each wall. Chords may also need to be reinforced before implementing.

FOUNDATIONS:

EXISTING CONDITIONS

- Foundations for these buildings are often stone rubble or stacked granite and lack any sort of anchoring. Retrofitting modern anchors becomes difficult because the stones are not connected (even when grouted), so anchors only engage the top course.

IMPROVEMENTS

- Completely new foundations. Usually, the most expensive option and often less chosen, shoring the superstructure above, removing the old stone foundation, and reconstructing using modern techniques will create the best foundation to anchor upon.

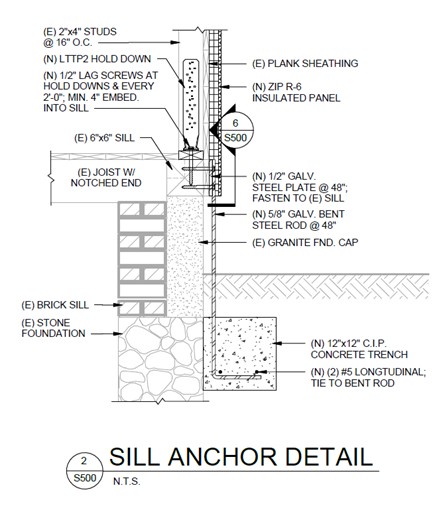

- Supplement with exterior foundations. If the existing foundation is in good condition, it should be able to handle the gravity loads of the building, and supplemental foundations can be designed to counter only the uplifting forces of the shear walls. New foundations can be creatively designed around the exterior of the building, such as a concrete trench anchored to the exterior walls. If continuous exterior insulation methods are used, anchors can be hidden within the insulation cavity.

- Supplement with interior foundations. In a similar approach, interior foundations can be supplemented to withstand just the uplifting forces. Often these methods are more challenging with the foundation walls protruding farther in than the wood walls above it. Said differently, a straight vertical load path is likely not possible and adds eccentric forces to the design.

Brian W. Ki, P.E.

Staff Engineer

More Articles From...

| This Category | Home Repairs, Residential Engineering, Structural Design, Structural Engineering |

| This Author | Brian Ki, P.E. |