New Heat Pump Technology: Air-to-water Heat Pumps

By Ali McNamara

The demand for efficient and sustainable heating and cooling technologies is ever increasing. Heat pump technology is continuously advancing to answer this demand by providing energy-efficient and low carbon emission solutions. By taking advantage of the refrigeration cycle (extracting heat from outside air), heat pumps can achieve 300% efficiency or more, meaning they can output 3 times the heating capacity than input electricity. For comparison, resistance electric heat is 100% efficient. Heat pumps can achieve this output using fans and pumps which only require electricity to run. Systems that require fossils fuel such as oil, propane, or natural gas release carbon dioxide and other greenhouse gases which contribute to global climate change. By utilizing a clean electric grid and heat pump system one can reduce their carbon emissions and impact on the environment.

An emerging heat pump technology that has been gaining momentum in the US is the air-to-water heat pump. Europeans have been utilizing this technology for years, and it is currently gaining popularity and becoming more available in the US. A whole home energy solution, the air-to-water heat pump can heat, cool, and provide domestic hot water. It is an important technology to consider as it provides a hydronic distribution system without the use of fossil fuels and is more efficient than traditional air-source heat pumps.

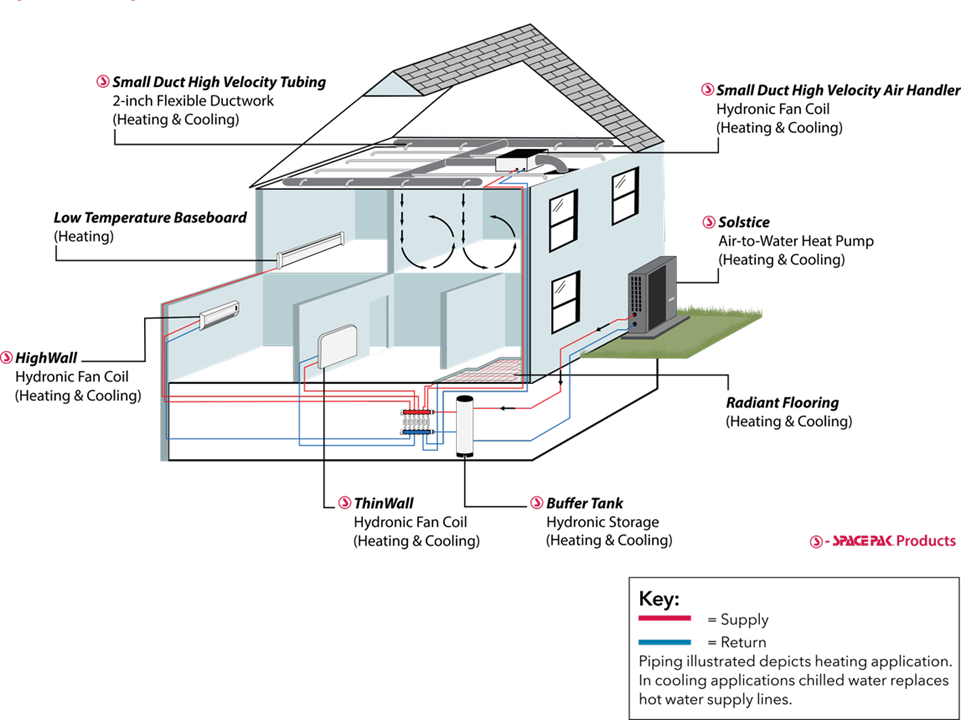

An air source heat pump utilizes the refrigeration cycle to transfer heat. Outdoor air is used as a heat sink where heat is either pulled or dumped to create a comfortable indoor temperature. Like any air source heat pump, an air-to-water heat pump uses outside ambient air to condense or evaporate refrigerant, the difference being water is the medium that conditions the space. In a traditional air-to-air heat pump system refrigerant is pumped to indoor units inside the building to cool or heat. In an air-to-water heat pump system hot or chilled water is pumped to indoor units or radiant floor systems. Domestic hot water can also be produced providing one integrated system. The air-to-water heat pump offers design flexibility as it can supply water for radiant heating and forced air systems via hot water and chilled-water coils. Like all forced air and radiant systems, these systems can be designed with zoning capability.

Example schematic of air-to-water heat pump and types of distribution Systems

Photo credit: https://www.spacepak.com/solstice-air-to-water-heat-pumps

Air-to-water heat pumps are best utilized in new construction homes or homes that are looking to implement a new HVAC system. Retrofitting with this system can be challenging. One drawback is that it cannot be a direct replacement for an existing gas-fired boiler and radiant distribution system. The typical baseboard radiant system used in many older homes requires supply water around 180°F when heating, while air-to-water heat pumps typically only produce water up to a maximum of 140°F and circulate 110°F when heating. Realistically, these systems operate best when producing 120°F or less water. This lower water temperature is perfect for radiant floor or radiant panel applications. The air-to-water heat pump is best for clients wanting a new system that is electric, energy-efficient, and has low carbon emissions. Clients interested in radiant floor heating should also consider this system.

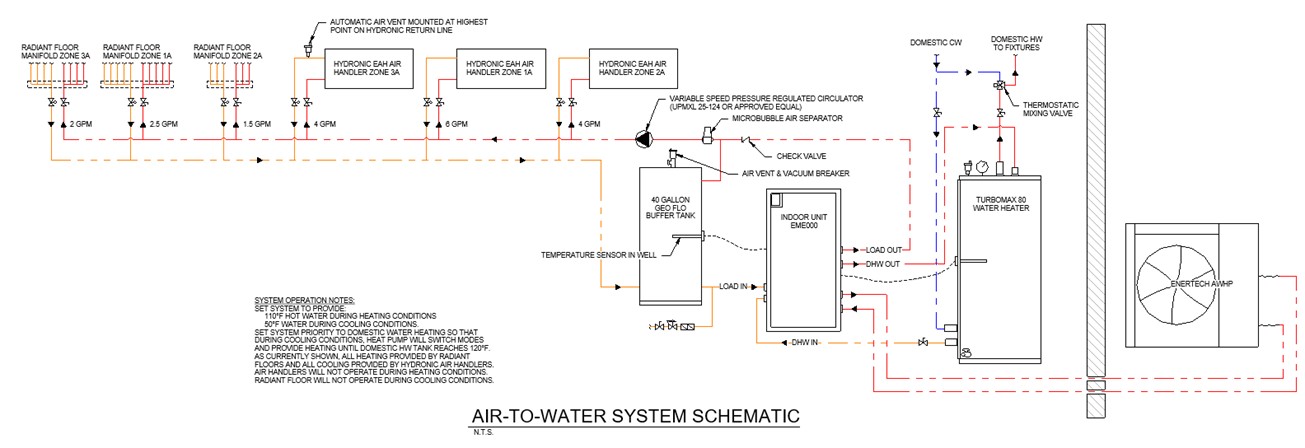

Recently, Team worked with a client that met this criterion who was interested in learning more. Engineers at Team designed an air-to-water heat pump system in their new construction, energy efficient home. In-floor radiant heating was designed to be the primary heat source, while hydronic air handlers with chilled water coils and ducted distribution were designed for cooling. During heating conditions, the air-to-water heat pump will provide hot water to an 80-gallon indirect water heater and the radiant floor loop. A 40-gallon hydronic buffer tank will store hot water for the hydronic heating or cooling systems. The buffer tank helps to add thermal mass to the system and prevents short cycling (when the system turns on and off too frequently and does not meet the conditioning needs). However, not all air-to-water systems require a buffer tank; compressors that are fully modulating may be piped directly to the load. During cooling conditions, chilled water is produced and piped to the air handlers. The outdoor unit reverses the cycle direction periodically to produce hot water for the domestic tank and switches back to cooling when the tank reaches 120°F. Priority of hot water production or chilled water production can be set to ensure cooling can happen without sacrificing hot water production.

Engineers here at Team are excited about this new technology and how it can be utilized. While it may not be a solution for every client, it is an important technology to explore and consider. The high efficiency of this technology and the ability to provide heating, cooling, and domestic hot water with one system make this an exciting option.

Team Designed Schematic of Air-to-water System Layout and Flow with an indirect water heater, 3 zones of radiant floor heating, and 3 air handlers.

Ali McNamara

Engineering Assistant

More Articles From...

| This Category | Educational Training, MEP, Residential Engineering |

| This Author | Ali McNamara |