Utilizing Steel Frames in Modern Residential Architecture

By Morgan Daley

Structural steel is key to unlocking the full potential of modern home design. Recently, Team Engineering has had the privilege of providing structural designs for several exceptional homes, showcasing the advantages of steel in residential architecture. These projects have highlighted key factors contributing to the success of steel-driven designs.

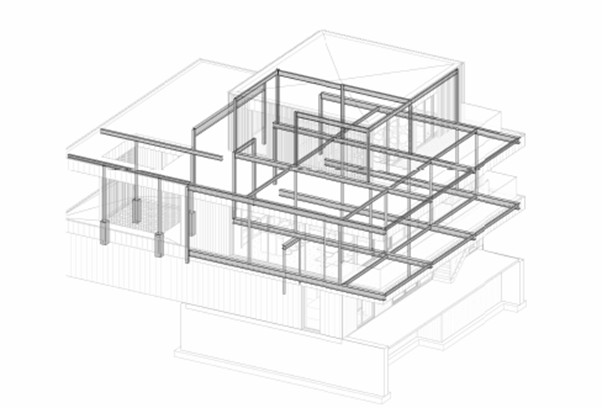

Figure 1: Contemporary Lake house featuring multi-level cantilevered decks. Designed by ACDF Architecture.

- Early Communication of Design Intent

The most successful projects include open discussions as concepts emerge. When architectural plans are provided for a structural concept review at the outset of a project, it allows for the identification of areas where steel framing may be well-suited. This early review provides the contractor and client with the opportunity to incorporate these costs into the project budget, helping to avoid unexpected expenses when bids are received after the plans are finalized. Establishing this line of communication from the start can prevent costly redesigns and minimize delays to the construction timeline.

2. Multi-Disciplinary Coordination

M.E.P. components interacting with steel systems is more complicated than wood framing. Creating openings for these elements requires extensive analysis coordination and can significantly increase fabrication time. Additionally, there are limitations on how many openings can be made in a steel member without compromising its strength. Given these challenges, it is crucial to involve an MEP design team early in the process. Early collaboration allows the team to coordinate their systems with the structure and influence architectural decisions, such as determining the required ceiling depth to accommodate

both the structure and mechanical components. It also helps optimize the placement of mechanical units and rooms to minimize the length of duct runs and avoid interference with steel elements

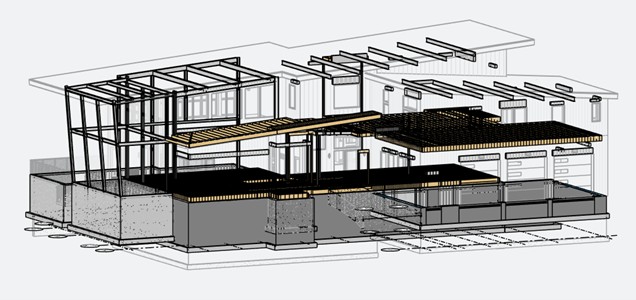

Figure 2: The system of repetitive steel frames utilized to achieve ACDFs vision.

3. Embracing the look

A review of the AISC Steel Construction Manual quickly reveals that steel shapes are not designed with the dimensions of conventional lumber in mind. For example, fitting steel columns into a 2x

stud wall frequently poses a challenge, especially when insulation is required to prevent thermal bridges. Similar issues arise in floor and ceiling systems, where the dimensions of steel beams rarely align with those of a conventionally framed wood structure. However, when architecture is designed with steel in mind, it can be used as a design feature. Exposed steel, when paired with wood finishes, can create a striking visual contrast, as shown in Figure 3. This approach also provides the structural team with greater flexibility to design steel members optimized for the specific loads they need to support rather than attempting to force the steel to meet both load-bearing requirements and dimensional constraints imposed by surrounding wood elements. This leads to a more efficient and cost-effective steel design.

Figure 3: A striking example of exposed steel as an architectural feature. Presented as inspiration for a design by Winter Holben (Figure 4)

4. Engage a knowledgeable steel fabricator

A well-designed structural steel system is only effective if it is built correctly. The process of producing steel shop drawings, fabrication, and erection is highly detailed and requires precise

Figure 4: Structural model for a steel forward design by Winter Holben architecture. Which drew inspiration from the home displayed in Figure 3

coordination with both the architectural and structural plans to ensure everything aligns as intended. It is essential for the construction manager to bring on experienced and knowledgeable steel contractors. When inexperienced contractors are engaged, it often becomes evident through poorly constructed shop drawings that do not align with the submitted plans. This misalignment can lead to numerous issues, including multiple rounds of steel shop reviews and resubmittals, on-site framing inspection to ensure proper installation, and, in the worst cases, costly and time-consuming change orders to correct or accommodate incorrectly installed steel members.

Integrating structural steel into residential designs offers unique opportunities that can open previously unattainable design possibilities. While it may present a challenge for those new to this level of steel involvement, these projects can be effectively managed with a focus on embracing steel, fostering clear communication, and ensuring the involvement of a skilled and experienced design team. With the right approach, the process can be seamless, and the end results can be spectacular.

Morgan Daley

Engineering in Training

More Articles From...

| This Category | Residential Engineering, Structural Design, Structural Engineering |

| This Author | Morgan Daley |