REINFORCING EXISTING ROOF FRAMING AND TRUSSES – WHY AND HOW

By John Turner, P.E.

Designing roof framing for new buildings is relatively easy. Most of our architect clients already have a solid vision of the basic materials, methods and layout. Our job is to insure we understand the construction type, research local snow, wind and seismic loads, plug the Revit model into RISA (structural design software) and solutions emerge – all the way down to the foundation.

understand the construction type, research local snow, wind and seismic loads, plug the Revit model into RISA (structural design software) and solutions emerge – all the way down to the foundation.

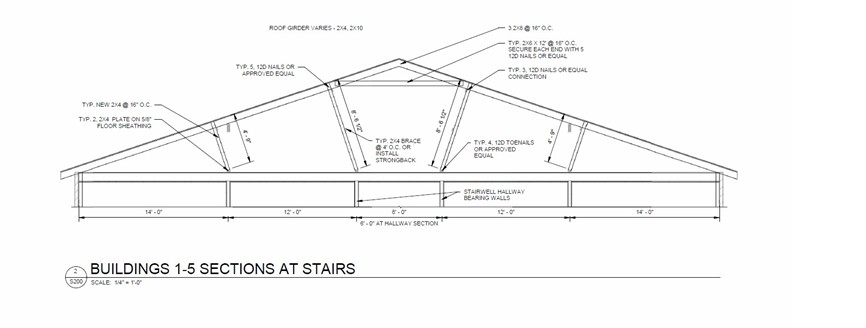

Existing building modifications are where we often get more challenged. Working in New England gives us plenty of opportunities to improve roof framing. The need stems from original framing that is typically undersized. Building owners naturally want to add insulation, solar panels, or make other building modifications that add load to their roofs. One of my favorites from last year is in the photo on the right. The owner of this apartment building wanted solar panels installed on the roof. The original roof framing was not even close to supporting likely snow loads – let alone adding the solar panels. Our solution was delightfully simple (section view below) – add braces that put the roof load directly onto the hallway bearing walls below. The owner reported that our solution cost 1/3 of what another engineer had designed.

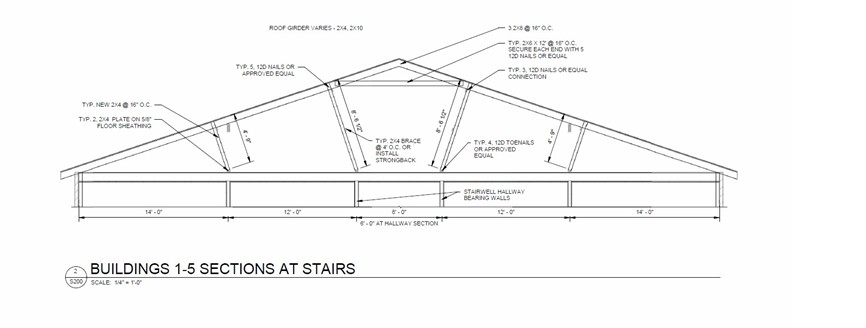

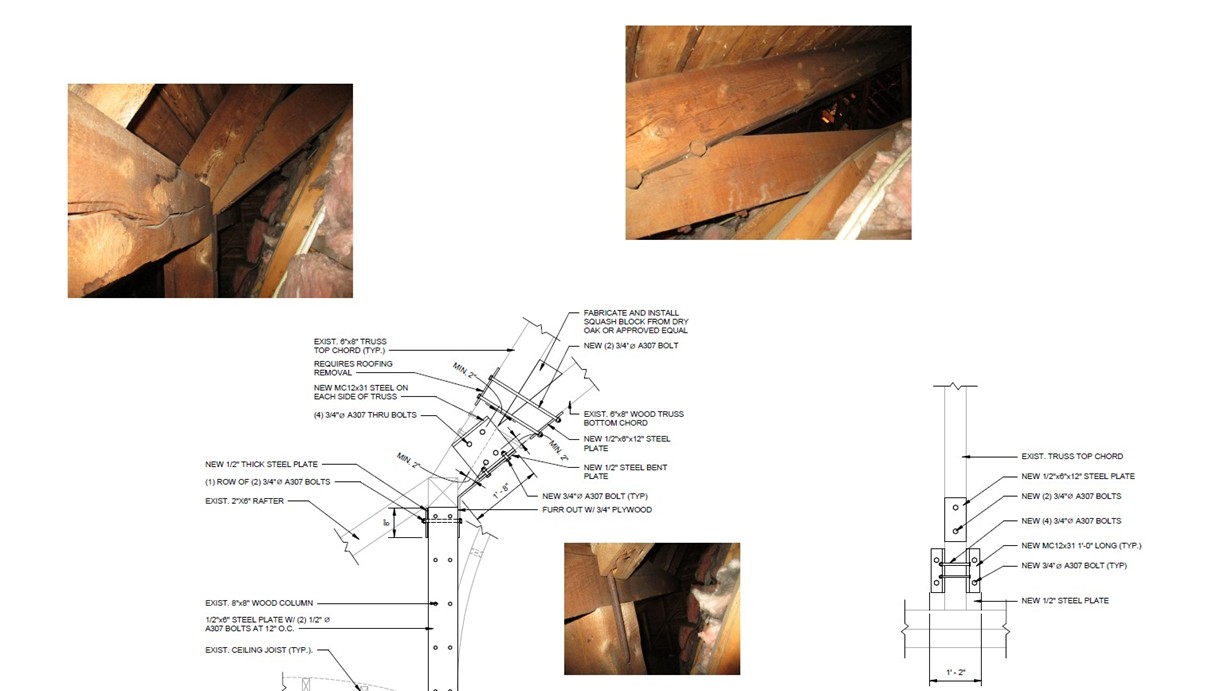

Most of our roof reinforcement projects are far more complex. Over the years, we’ve tackled lots of trusses and roof framing in older buildings. Many of these are constructed with timber frames trusses. It’s probably no significant surprise to those in the industry that connections are typically the weakest member in a truss. This applies especially to mortise and tenon joinery where the  actual strength of connections is extremely difficult to definitively analyze. We have also found that snow load does not always drive the need for reinforcement. In the photo at left, North Branch Construction implemented our truss improvement design on this and 9 other similar connections. In this case, it was wind and associated uplift that became the controlling element at the post/bent connection. The custom steel connection plates and bolts became a crucial element to handle the wind loads of this 20 pitch roof!

actual strength of connections is extremely difficult to definitively analyze. We have also found that snow load does not always drive the need for reinforcement. In the photo at left, North Branch Construction implemented our truss improvement design on this and 9 other similar connections. In this case, it was wind and associated uplift that became the controlling element at the post/bent connection. The custom steel connection plates and bolts became a crucial element to handle the wind loads of this 20 pitch roof!

We often incorporate photos in our designs – as shown below – to help the contractors understand our vision for the repair. The variation in details of each connection at this structure became quite a challenge for the installation. However, North Branch did a fantastic job with the execution.

Usually, it is difficult and economically infeasible to bring the entire structural system into compliance with “current requirements”. Again, this is where engineering judgement (and cooperative Authorities Having Jurisdiction) come into play – as we will often recommend improvement – not perfection.

Many in the industry agree that the Codes for snow, wind and seismic loading are very conservative. In general, we agree. However, as an example, Boston got over 9’ of snow in 2015 – largely in the month of February. And this year, Jay Peak reports nearly 400” of snow – a good reminder that the locality of our projects should greatly influence our design solutions. Point is, serious snow accumulation is reality that we need to design for.

So, it is certainly appropriate to evaluate existing buildings and to contemplate improvements when warranted.

John Turner

Senior Engineer

More Articles From...

| This Category | Residential Engineering, Structural Design, Structural Engineering |

| This Author | John Turner, P.E. |