LESSONS LEARNED DESIGNING METAL BUILDING FOUNDATIONS

By Dan Martel, P.E.

Metal Building Systems are understandably popular. We’ve seen them economically meet project requirements for long spans and limiting the number of interior columns. They make great sense in buildings used for fulfillment, storage, manufacturing, and athletics.

In the last five years alone, we’ve been involved with more than (10) projects utilizing these systems, and our most important lessons involve the foundations. The steel superstructures are designed very precisely by the specialist engineers employed by the manufacturers, who rely on us local engineers to design the foundations.

Caption: A single-span metal building addition to a manufacturing building in Londonderry

A 3-span metal building with a 40-foot clear height, used for a fulfillment center in Rochester

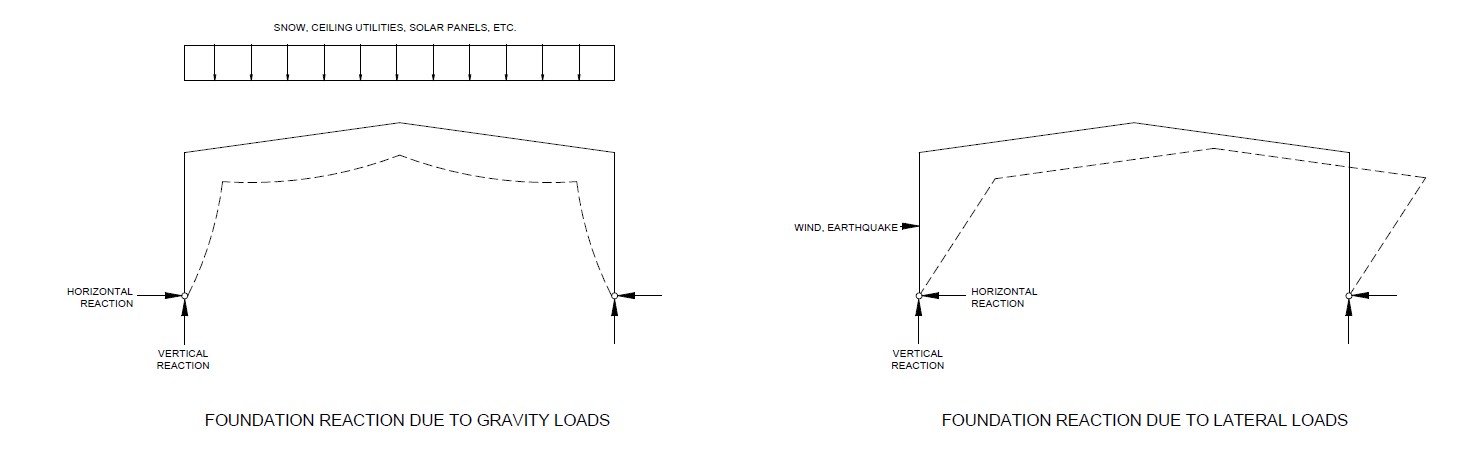

The buildings often utilize rigid frames, with moment-transferring connections at the ridges, eaves, and interior columns. The action of these frames results in large lateral loads at the column bases not just from wind and earthquake loads, but even more so from roof gravity snow loads. The buildings are very light, so there is less friction-creating weight at the foundation to resist lateral loads.

Caption: Typical Loads and Rigid Frame Action

Our approaches to counteract these lateral loads include:

- Sometimes, the mass of the footing, the size governed by the soil bearing capacity, produces enough friction to resist the lateral forces. Great.

- We can increase the size of the footing, utilizing the 150pcf concrete mass to produce more friction resistance.

- We can tie the footing to the adjacent walls to engage more passive resistance of the soil backfill.

- Provide direct tension connections between the footings to produce opposing reactions. We’ve accomplished this using steel rods welded directly to the column base plate.

Caption: Tension rods tied the opposing foundation, creating equal and opposite reactions to the outward lateral forces.

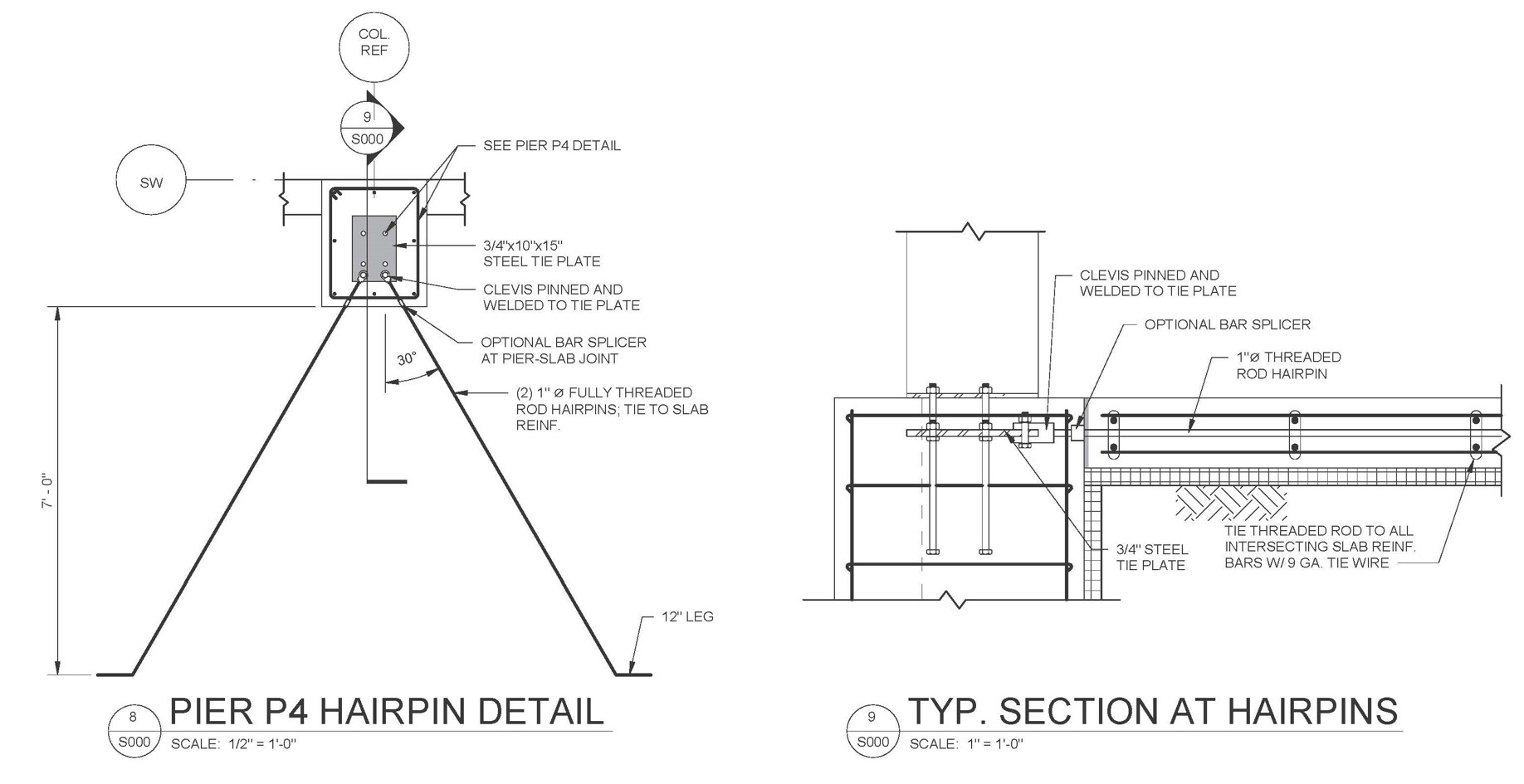

5. Engage the concrete floor slab to provide more friction resistance. On multiple buildings, we’ve designed “hairpins” that are fastened to the anchor bolts, then tied to the slab reinforcing bars. Tension resistance can be maximized if hairpins are provided on both sides of the frame, and there are no construction joints in the slab. The drawback to this approach: if the slab is modified in the future by cutting or removing, the opposing friction forces can be unknowingly and detrimentally reduced.

Details for hairpins connecting the metal building columns to the floor slab, which will act as a tension element opposing the outward forces

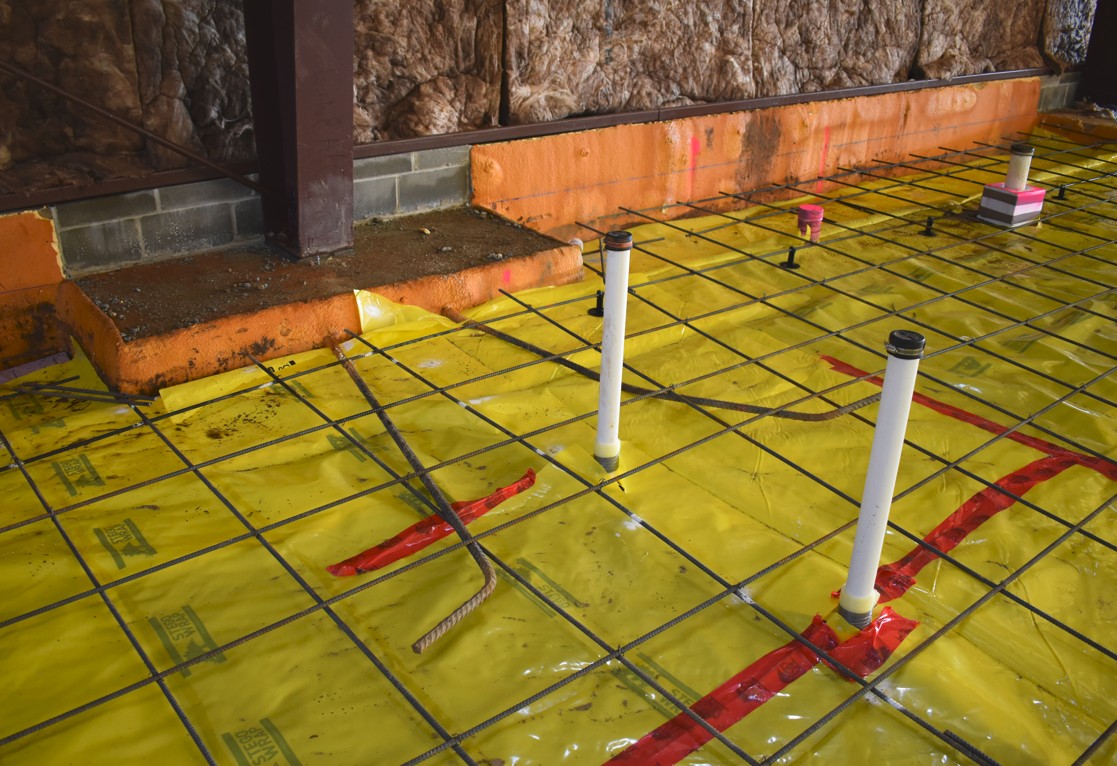

Caption: Hairpins tying the metal building columns to the floor slab, seen during foundation construction at the Rochester fulfillment center

Caption: Hairpins tying the metal building columns to the floor slab, ready for slab concrete

These metal buildings are simple and structurally efficient, we’ve successfully utilized practical and creative strategies to produce effective foundations to suit the building and site parameters.

Another type of pre-engineered building – arch trusses with a fabric roof – that can produce high lateral foundation loads

Dan Martel

Senior Structural Engineer

More Articles From...

| This Category | Structural Design, Structural Engineering |

| This Author | Dan Martel, P.E. |